Hydronix achieves significant CO2 and financial savings at busy readymix & plant

£185,000

Annual Saving

1030t

Annual CO2 Saving

2460%

Return on investment

A leading roof tile producer had been using a rotating pan mixer for about 30 years at one of their busiest plants to produce their challenging mix design of semi-dry, all-fines coloured concrete.

The mixer featured a high intensity rotor with high shear mixing action for effective pigment distribution, however, power consumption, maintenance costs & dust leakage were all high.

The engineering manager decided to investigate whether other mixer designs with different mixing actions could achieve the same high quality of output but with fewer costs and issues.

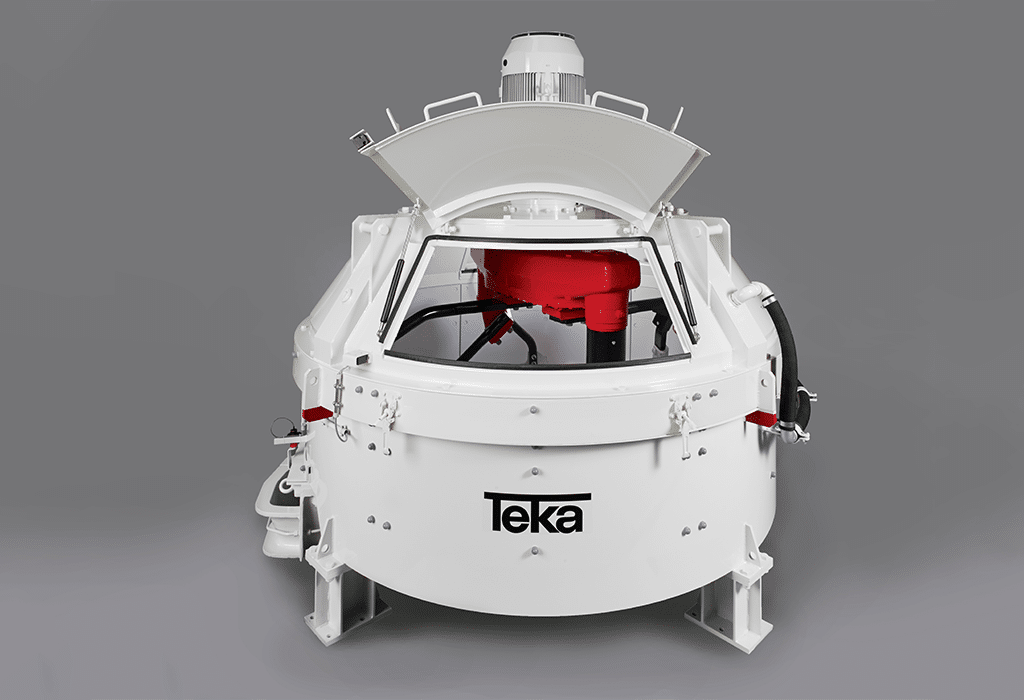

Following the successful installation of Teka mixers at another group production facility, ConSpare were asked to assess replacement of the existing mixer with a Teka planetary mixer.

Concerns were raised about changing mixing action, but ConSpare were confident that Teka would meet the high quality standard and provide a more sustainable solution.

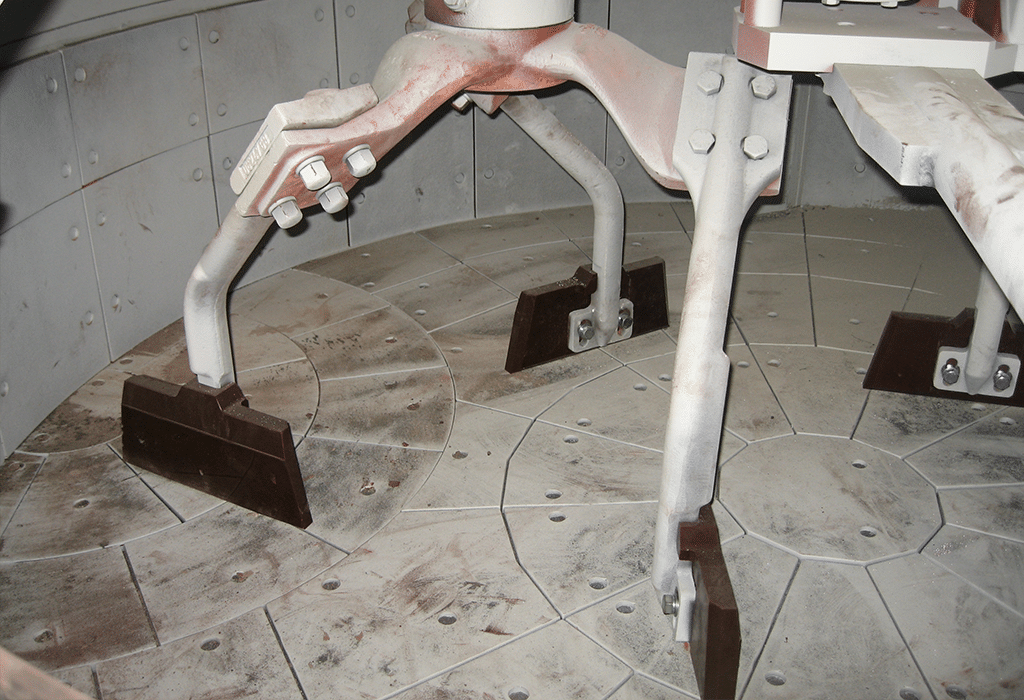

In 2010 ConSpare delivered a Teka TPZ1500, with a high efficiency gearbox driving two counter-current mixing stars which give an intensive mixing action with a low power consumption.

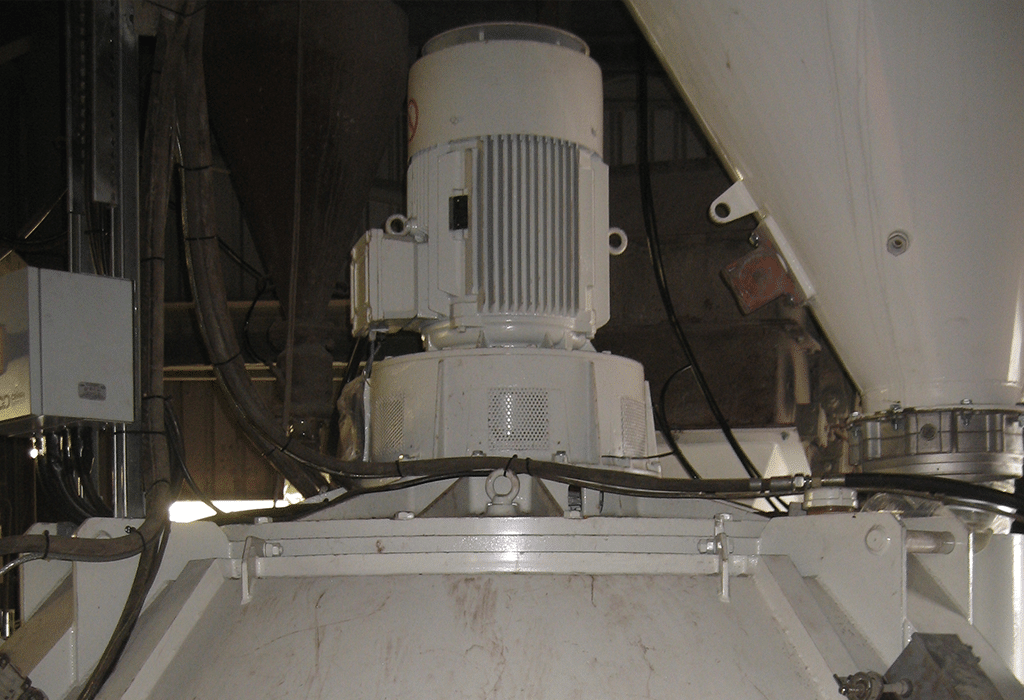

The 1m³ output TPZ mixer has consistently achieved the same mix quality & production volumes using only a 45kW drive motor, compared to the 82kW drive system fitted to the previous mixer.

The company operated both mixers for 2,500 hours per year at around 75% of maximum rated power, meaning that the Teka mixer has been saving over 68,000kWh of power per year.

(Image: 82kW drive system reduced to 45kW with Teka TPZ1500)

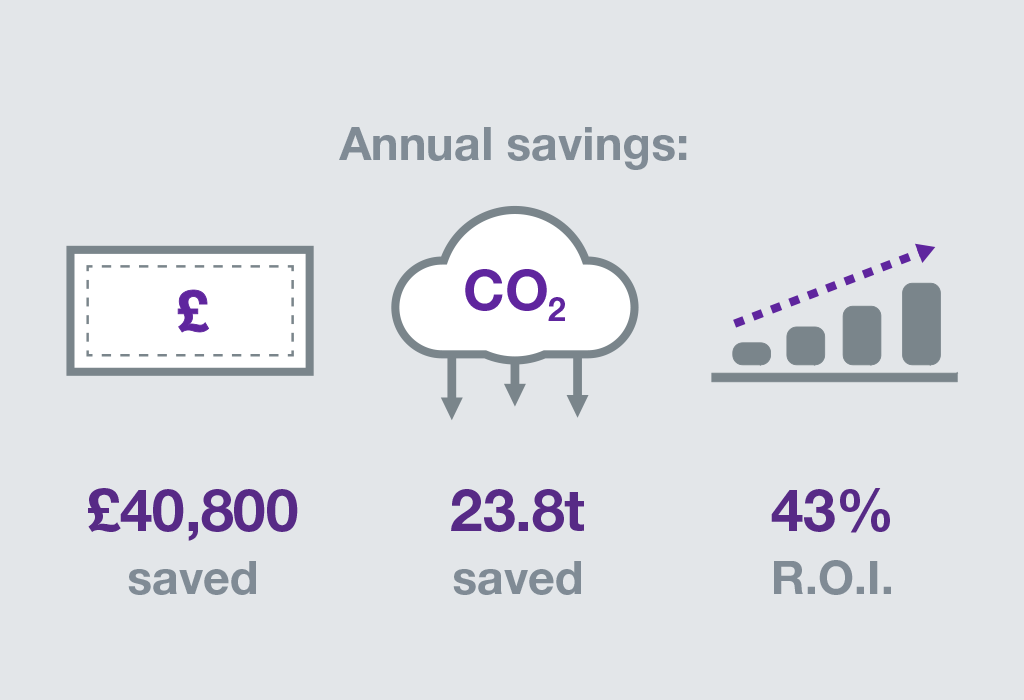

The Teka mixer was installed 12 years ago and could therefore have saved a total of 816,000kWh. At a rate of 60p per kWh this means the annual power cost saving is £40,800.

Based on power cost savings alone the mixer has paid for itself more than twice over during the 12 year period.

Over the period in question the UK emitted an average of around 0.35kg of CO2 per kWh generated. This multiplied by the total power saving gives a total CO2 saving of 285 tonnes.

The client reported that the Teka mixer used 70% fewer spare parts per year, which also has an environmental impact due to the amount of steel and tungsten these parts contain.

(Image: Counter-current mixing stars give high efficiency mixing)

Further financial and environmental savings have been made by a reduced need to buy, transport and install spare parts, which also reduces the need for site staff to enter the mixer pan.

Since the first installation, the company has invested in several more new Teka mixers, contributing significantly to producing more sustainable, lower carbon roof tiles at a lower cost.

In Brief:

• Teka TPZ replaced rotating pan mixer in 2010

• Mixer drive motor power decreased by over 40%

• Power saving of over 800,000kWh to date

• Power saving to date worth over £200,000

• A total of 285 tonnes of CO2 saved so far